THIS IS THE ORIGINAL PLAN DRAWING FOR IBIS--FOR THE FINAL REVISED PLAN, SEE THE "REVISED" CONSTRUCTION PAGE  |

|

The Big Tent; Lots of plywood |

Bulkheads set up on the Strongback |

The Apron, bow knee and chine logs |

The apron, breasthook and sheer clamps |

Stern post, sheer clamps & chine logs |

Stern post, breast hook and sheer clamps |

Stern post, chine logs and keel plank |

First of two diagonal bottom plank layers going on (note correct beverage) |

First bottom layer done; topsides planking is next |

The hull is planked; Outer stern post on |

The keel looking aft; the gripe is solid yellow pine, the keel is hollow-box |

The keel looking forward; the aft bottom will be solid plank; plywood bottom amidship |

The finished keel with stern tube installed |

The stem/gripe joint in the bow; note wood fillets |

The stem; the hull is ready for Xynole Epoxy |

The Xynole/epoxy covered hull in

primer, ready to be turned over The Xynole/epoxy covered hull in

primer, ready to be turned over |

Righting the hull using square wheels and a gantry |

The hull right side up, back in the tent |

The cockpit roughed in; lazarette hatch frame aft |

The holding tank/head platform |

The port side 150 gallon integral water tank (also the master cabin bunk) |

The master cabin berth; furring strips are for ceiling planking |

Shelves in the master cabin, roughed in |

Companionway steps into the aft cabin |

Aft cabin; galley drawers |

The foc's'le V-berth with foremast tabernacles |

Fore deck beams; forepeake locker forward |

Looking into the head from the forward cabin; companionway to left |

The side deck beams in place |

Side deck beams |

The cockpit; deck and coamings |

Deck underside; I pre-varnish beams and pre-paint the deck underside |

Decks are on, ready for Xynole/epoxy |

Mainmast tabernacle and stbd side hatch frame above master berth |

Solid wood cabin corner |

The mooring bitt and forepeak hatch opening |

Companionway hatch coamings and coachroof beams |

Rabetted coachroof beams for

foam core construction; sealed and varnished

|

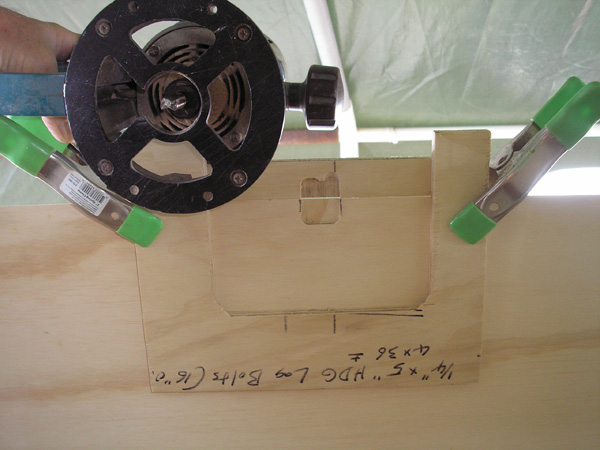

Router & template for beam mortises in cabin sides |

Hatch carlins |

Hatch covers Xynole/epoxy covered |

The aft cabin coach roof with hatch turtle and Lewmar skylights |

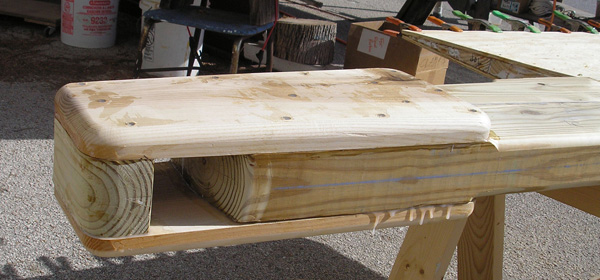

The first bulwark layer being lag bolted |

First layer finished |

Adding the second bulwark layer |

Prying the layers apart to apply epoxy glue |

Bulwarks bunged, ready for

shaping & Xynole/epoxy

|

The finished boat in primer |

IBIS shrink-wrapped for the summer of 2008 * * * * * |

Upon my return in Fall of 2008, I painted my topsides first |

Making cabin top hand rails from teak plank stock (heavy duty) |

Finished hand rails ready to be installed |

The cabins and decks painted with Dupont Industrial Imron (custom color) |

The cockpit, lazarette hatch and pedestal |

A Lewmar size 50 Ocean-Series skylight installed (typical) |

Cargo hold deck hatch |

The deck skylight over the master cabin double berth |

The sliding hatch for the forward cabin companionway |

The mainmast tabernacle and water tank vent |

The galley refrigeration compartment and countertop |

Drawers, shelf and saloon table, made from wild black cherry (from my own trees in Maine) |

Galley drawers

|

The rudder from solid core stock ready for plywood sheathing |

The rudder core |

The rudder with plywood sheathing |

Rudder cheeks |

The rudder with template for Naca 009 foil shape |

The rudder with end plate ready for Xynole/epoxy |

The finished rudder in primer |

Using a chop saw with blocking to cut scarfs in mast timber |

Mast panels ready for assembly (bird's mouth method) |

Mast glued up using rope strop clamps |

The mast power planed to an octagonal shape |

Power planed to 16 sides |

Power planed to 32 sides |

Using a low-speed body grinder with 8" soft pad for final shaping |

Reducing the mast head for the SS collar |

Dry fitting the collar--rounding the head |

Cutting out booms from solid Douglas fir stock |

Using a long twist drill to transfer shape to the opposite side |

Finished boom (left); Sawn boom (right) |

Gaff jaws cut for laminating shape (mahogany) |

Laminating gaff jaw curvature |

Boom jaws sawn from mahogany stock |

Making bee rail components (mahogany) |

Bee rails--one side containes Delrin sheaves |

Aligning boom jaws for drilling holes for SS allthread |

Stainless steel chainplates, mast collars, rudder gudgeon |

Rudder hardware--virtually indestructible! |

Rudder hardware being dry-fitted |

Rudder pintle |

Rudder gudgeon being dry-fitted |

Rudder hardware attached (through-bolted) |

The rudder hung; Ash tiller in place; Rubrails on |

IBIS! Bowsprit on |

Propeller shaft, Phenolic cutlass bearing, set screws, ready for prop |

The stuffing box and shaft flange plate |

The A-frame for tabernacling the masts being dry-fitted |

Starting the steel centerboard--frame and sides |

Bill Smith welding the upper strut extensions |

Installing lead ballast in the centerboard |

Cutting for strut welds |

The ballasted lower part finished--the upper struts ready for plating |

The centerboard bottom is shaped from black pipe |

Slot welding the internal struts |

The welded board ready for grinding; The hole is for the pivot pin bushing; Square part stays inside the trunk; foil part becomes a fin keel when deployed |

The hollow upper part prior to finishing |

The finished centerboard ready for grinding and Xynole/epoxy covering |

The cockpit finished |

The midships bridge deck, cargo hatch and hardware |

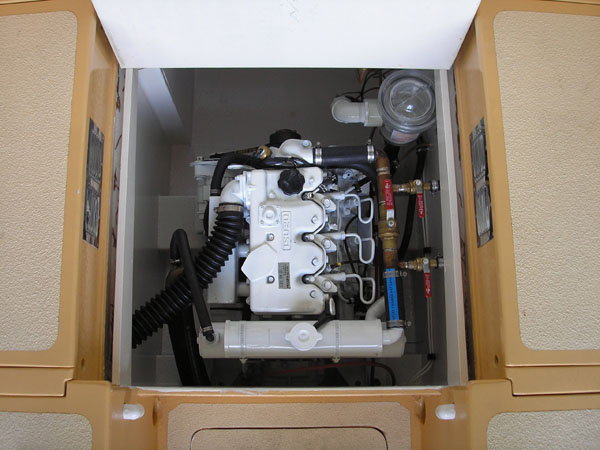

The Isuzu 3LD2 ready for paint |

Gaff jaws, boom jaws and bee rails varnished |

The patent stern (AKA boomkin) roughed out |

IBIS with bowsprit, A-frame, rubrails, chainplates, etc |

Stern with rudder and rubrails on, ready for the pattent stern |

The Isuzu refurbished and ready for installation |

A strum box made from PVC |

The bilge pump |

The water strainer |

Fuel pickup installed thru a delrin thru-hull fitting in an integral tank |

Fuel return utilising a tank vent |

Bilge pump (left); aqualift muffler (right); float switch & strum box (bottom); Motor mounts P & S |

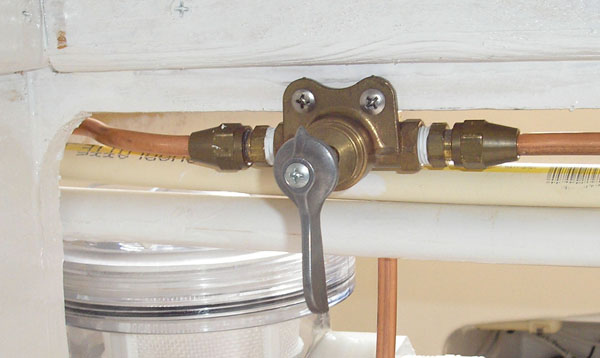

Fuel tank selection valve |

Fuel Filter |

The finished cockpit and patent stern |

Patent stern |

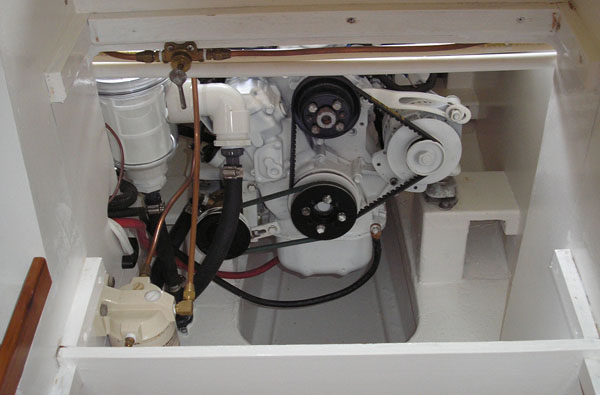

The Isuzu diesel installed; Manifold for the domestic water heat exchanger (right) |

Binnacle, compass and engine controls |

Shaft hookup featuring a Drivesaver (red) to isolate the electrical system from seawater |

The battery box and switch--two additional batteries are out of view to the right; Batteries are 6 volt deep-cycle golf cart type |

Battery box under the saloon settee; Battery switch (vent to right) |

Companionway steps & USCG required plaques |

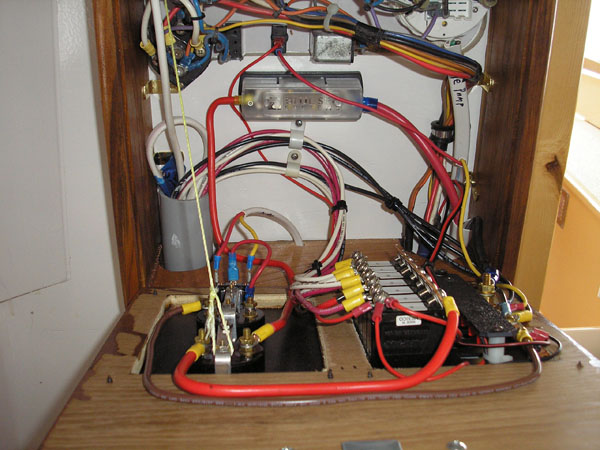

Electrical panel (12VDC only) |

Electrical panel guts |

The diesel with companionway steps removed to access front |

View from above, inside saloon, steps removed |

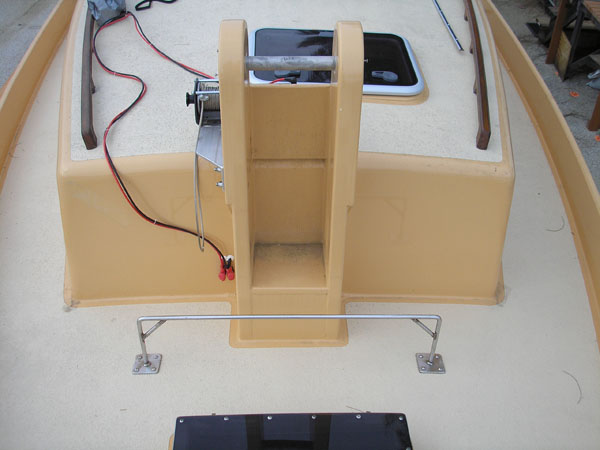

The foremast tabernacle, electric winch and jib sheet traveler |

The A-frame for lowering the masts; Twin anchor rollers |

A-frame Hinge |

The end of the A-frame; Cheek block; forestay chainplate |

Custom made anchor roller |

A-frame hinge from outside |

Foremast and rigging |

Measuring for a liverpool (marine) wire rope splice (18" for 5/16" wire rope) |

Tools for splicing |

Starting to wrap with tarred polyester for the thimble |

The thimble bight wrapped (served) |

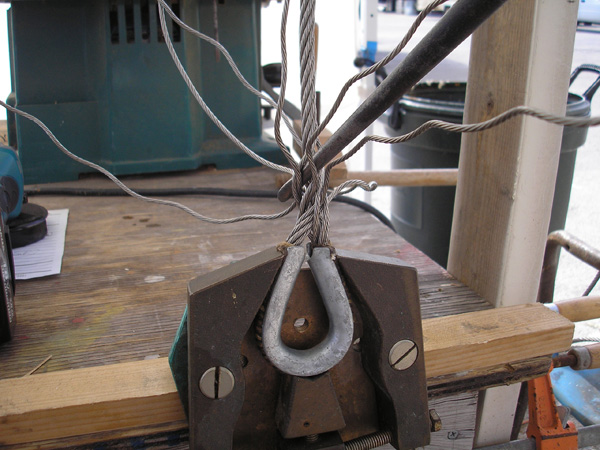

In the rigging vise |

Starting the splice; The thimble is stainless steel as is the wire rope |

Continuing the splice |

Using the spike to render a strand in |

Rolling the spike up behind the strand |

Slices served with SS seizing wire; Hot dip galvanized rigging screws; I buy half jaw & jaw, and half eye & eye to make jaw & eye |

Splice served with tarred marlin (polyester) prior to serving with anealed SS seizing wire; Splices aloft have marlin only; Splices below have SS seizing wire |

Mast head with both standing and running rigging attached; Lewmar blocks |

Boom end ready for Bee rails |

Mahogany bee rail with bedding compound ready to install |

Attaching the bee rail (rope end side) |

Attaching the bee rail (sheave side) |

Method for making off to a bosun's chair for going aloft unassisted (BEST WAY!) |

The seagull view... |

IBIS rigged and anxious for salt water... |

Using a lathe to turn ash belaying pins |

Ditto |

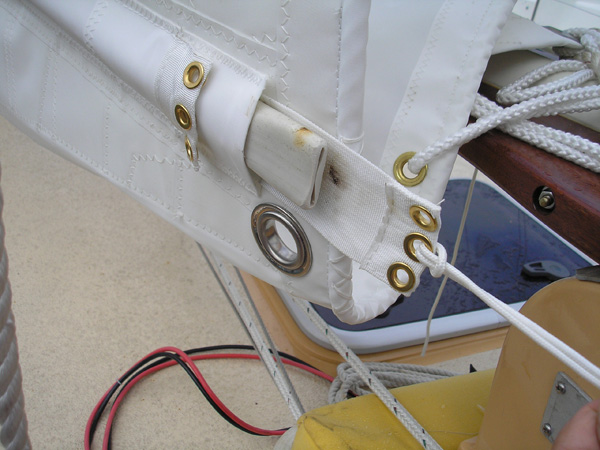

Chain plate; Rigging; Jib sheet fairleads; Lemar portlights; Gallows aft; Bimini |

Gallows and mainsheet traveler; Note patent stern brace |

Foremast; A-frame as bow pulpit |

Belaying pins; Boat hooks; ash oars, etc |

Chisels for lathe turning |

Masts down; On the trailer; Antifouling paint on; Centerboard on the left |

Beautiful! |

YES! |

In the Travel Lift |

Lowering onto the centerboard |

SHE FLOATS! |

Captain Parker looking a little worse for wear... but happy! |

Making sail battens with fiberglass cores and PVC covers flattened with a heat gun |

A batten inside the pocket (installed from the luff) |

Batten pocket closed |

Fores'l raised for the first time |

Mains'l raised; Note tack and clew rigging |

leather chafe gear on boom jaws and tabernacle heads |

IBIS's rudder had too much counter balance, and I re-proportioned it after our 2010 Bahama's cruise |

One of two side davits; IBIS can launch and retrieve her 14' tender under sail or power! |

The access plate for the aft end of the centerboard; The SS bolt below pins the board in the up position |

Ground tackle: 30 lb Delta plow (stbd roller); 55 lb Hereshoff (port);15 lb Danforth (stbd); A 10lb Danforth is carried as a stern kedge (see below) |

Mooring bitt with correct hitch; Anchor chain deck fittings |

The Hereshoff (fisherman) anchor and cat head--indispensable for rock and sandstone bottoms |

The stern kedge and deck fitting |

The stern kedge rode is kept in a 5 gal bucket inside the lazarette; clean and easy to take where you need it |

The bow rollers and anchor grabbers |

I sold IBIS in December of

2013 to a man from New Jersey. Despite what a wonderful, handy and fast

cruiser she is, I had never intended to keep her. I had been trying to

sell her for two years, and kept lowering my price. But the only offer

that came in required that I use owner financing... a HUGE mistake!

The buyer refused to make payments, and I was forced to repossess the boat. This took two years, and cost thousands of dollars. I had to sail IBIS to Florida from New Jersey in November/December of 2015 after making emergency repairs at Holiday Harbor boatyard in Waretown, NJ. I documented my solo trip--The Delivery From Hell--in my WoodenBoat Magazine Blogs. When I arrived back in south Florida, I spent many weeks repairing and modifying IBIS, before selling her to a wonderful family from North Carolina, who love her and appreciate her. You can study the repairs I made in a seperate CONSTRUCTION BOOKLET. |