|

|

The Strongback bolted to the shop floor |

Laying out face widths for beveling the apron/forefoot unit |

Bulkheads erected on strongback stanchions; Transom & Apron assembly on; Sheer Clamps & Chine Logs on; Bottom planking started (first diagonal layer of two) |

Hanging topsides planking to scribe for cutting before installation |

Cutting topsides planking; Sheets forward are oriented vertically for scribing |

Topsides planking on; Second diagonal layer being dry-fitted |

Bow detail--The second bottom plank layer butts the topsides plank layer to finish flush |

The second and final diagonal bottom layer is on; Topsides planking (single layer) uses buttblocks |

The upper stem is from solid wood; The lower stem is laminated and fairs into the forefoot |

Rounding the chine edges to a constant radius |

The hull is right side up and deckbeams are in; The headliner is being dry-fitted; Cabinetry started; 1 1/2" polyurethane foam panels are inserted between deckbeams in concert with laying the deck |

Detail of the deck frame: Beam-to-laminated carlin components |

The galley in frame; Fore & aft bulkheads/web frames are 1/4" ply reinforced from behind as needed |

The cockpit showing 1/2" ply washboards laminated over 2x2 carlins & sheer clamps |

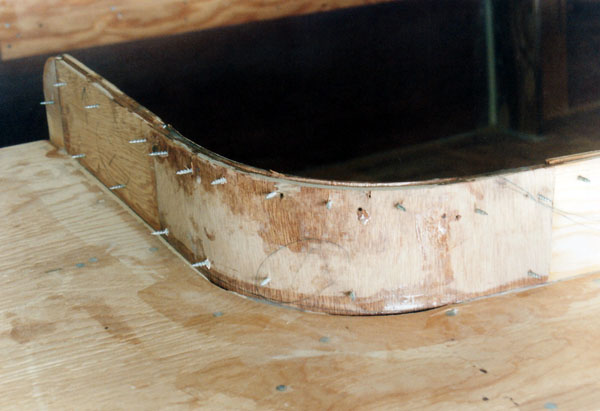

Detail of the cockpit coaming corner from outside (1/8" ply laminations); Screws are clamps |

The Cockpit coaming corner lamination from inside; Screws have been removed |

The cabin sides become the cockpit coamings; 1/2" plywood sides are scarfed to 1/4" ply laminates forward and are reinforced from inside aft by an additional 1/4" ply layer aft of the main bulkhead |

|

The laminated cabin front orients 1/4" ply grain vertically to make the bend |

All structural work is complete; Xynole/epoxy covering finished; Epoxy primers cover exterior work |

Masking for nonskid patterns; LP coats have been sprayed on all perimeters |

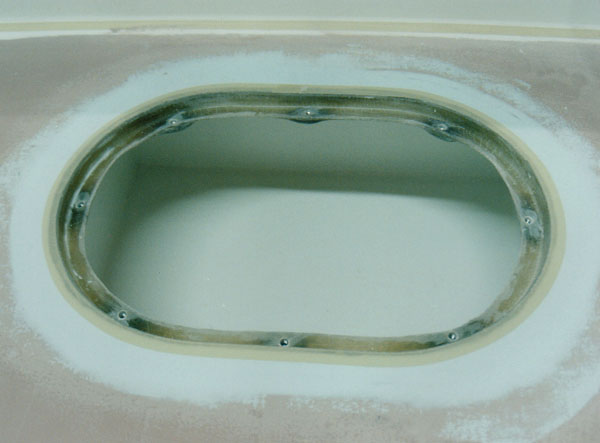

The manufactured fiberglass hatch insert spigot installed over the battery compartment |

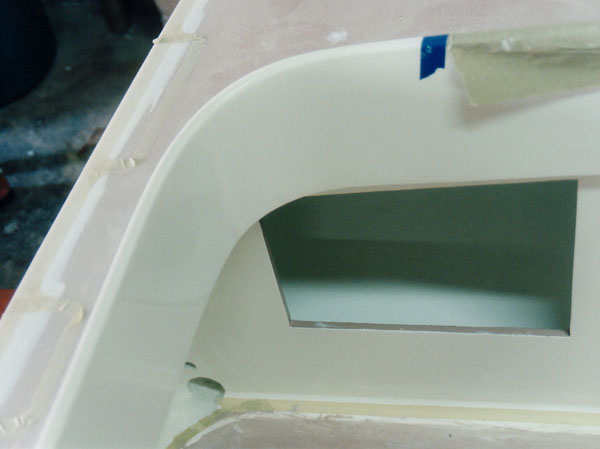

The cockpit coaming corner Xynole/epoxy covered, finished and LP painted; Note the lazarette locker, drain (small hole) and cockpit scupper (large hole) |

The galley under construction; Cypress ceiling planking laminated over 1x2 false frames forward |

A quick and dirty steam box for trim to be bent around the cabin front (inside & out) |

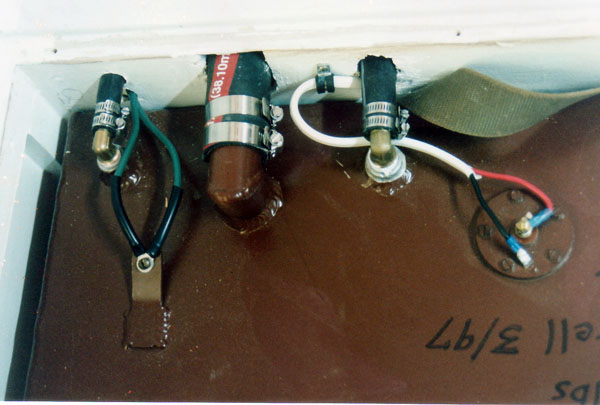

The aluminum fuel tank in place, bonded, wired (fuel gauge) & double-clamped hoses |

MAGIC is nearly finished; Hatches, Portlights, Deck fills, Cleats, Chocks, Handrails, Toe Rails, Cabin door, Bimini top and Honda 90 Outboard are all in place |

|

MAGIC emerging from a hole we punched in the shop wall with sledgehammers; Eleven weeks have elapsed since we laid the strongback out and started construction |

|

MAGIC afloat--right on her lines! Spring, Key West, Florida, 1997 |

|

The cockpit; the fuel tank is under the bridge deck |

A teak grating covers the self-draining anchor well--Best seat in the house! (Reuel's toes) |

The cockpit, looking aft; Batteries are under the flush hatch; Dock lines & fenders under the boxtop hatch |

The helm station; Steering is hydraulic |

The Galley and Electric Panel; The stove is alcohol |

The Lunenberg Foundries wood stove for chilly evenings exploring the Everglades |

MAGIC's saloon, showing double berth forward, settee berths p & s, dropleaf table, teak & holly cabin sole & cypress ceiling planking. Head & Icebox to starboard; Galley to Port |

|

MAGIC during initial sea trials; She exceeded all our hopes and expectations! |

|