Posts are set in concrete for mounting the bulkheads |

Bulkheads glued in sections with notches for longitudinals, etc (forward molds) Note the width of the flat-bottom hollow box keel |

The lowest portion of the traditional Caravel two-part transom |

The lower transom seen from the side showing curvature in lamination |

More bulkheads glued up in segments (aft molds) |

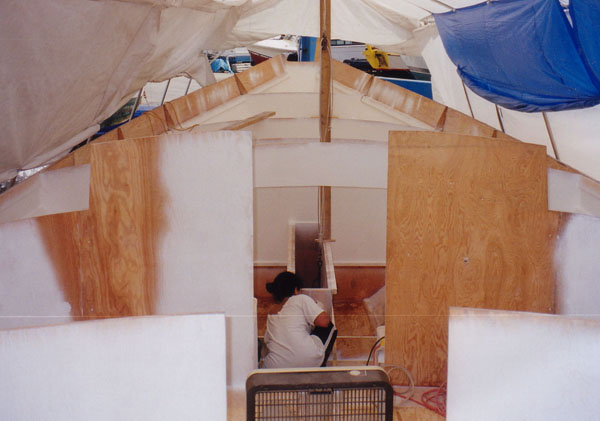

The Bulkheads and Transom are in place and the box keel is being assembled |

View of the box keel showing prop apperture and 2x2 cleats for the bottom plank |

The box keel finished and garboard planks are on--Note the Chinese bow |

Chine logs are beveled to receive 3/4" ply planking (two lam's below water); Fasteners are pneumatically driven galvanized ring-shank nails |

Middle planks are on |

Sheer strakes are on and the Bulwark planks are on |

View from astern |

Stern gallery windows cut out; Hull in primer |

The hull right-side-up |

Back in the tent; Pulling the trailer out from under the hull; Paint job not good, was re-painted |

Inside showing Retracting Keel Trunk, integral water tanks, etc The panels (foreground) are for the fresh-water-pump and wine cellar The platforms are for the galley furniture |

Steel angles reinforce the hull/bulkhead joints adjacent to the 3,500lb Retracting Keel Trunk |

Companionway steps from center cockpit into the main saloon; Integral 220gal fuel tank below |

Joint for chine logs; glass-tape over Bulkhead fillets, Sheer Clamp, Countertop, etc |

Engine Room under insulated foam-core cockpit well, Shaft Log to left |

The Holding Tank with Shaft Log running through it; Compartment aft was foam-filled |

The Hollow Box Keel aft of the holding tank was carefully sealed with epoxy and plywood covered before being filled with poured-in-place 4lb polyurethane closed-cell foam |

The aft cabin being roughed in |

View forward showing bulkhead extensions supporting Bulwark planks |

View from Center Cockpit into Saloon showing Keel Trunk |

Applying epoxy primer |

The Galley Sink and Drain Board under construction |

Delfine using a trim router |

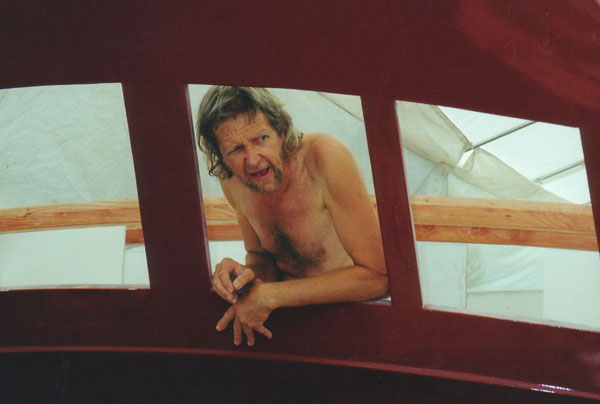

Stern view showing Aft Cabin Gallery Windows; Bill Smith below |

Captain Parker looks grouchy!

|

The Epoxy-mixing station; Delfine mixing Shell Epon epoxy |

Deck beams starting to go in |

The Parker Marine office in Riverside's old icehouse; Sticky Notes Rule! |

Working in the Main Saloon; View aft from the Cargo Hold |

Reuel & Delfine working in the Main Saloon |

Deck Beams & Hatch Carlins going in--Note the rabbets for headliners & foam cores The break in the deck steps up at the Main Saloon |

Deck Frame for the Cargo Hold |

Deck Frame looking forward |

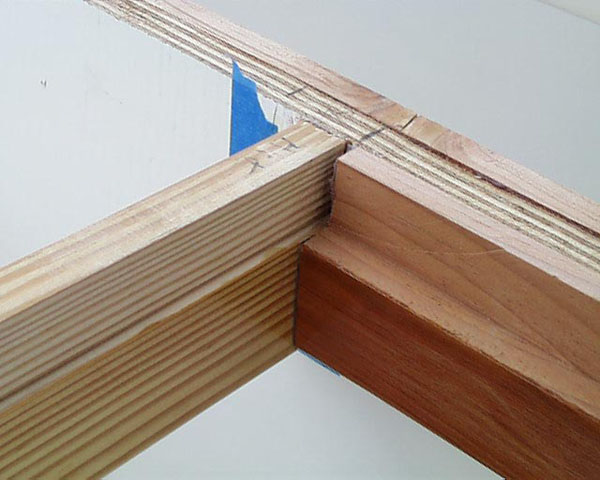

Detail: Deck Beam to Sheer Clamp inner laminate |

The same view from above |

Hatch Carlin to Bulkhead Cleat Beam Detail |

Delfine is countersinking staples in the Head Compartment Roof; Cockpit Coamings are finished and the Cabin Trunks are finished; Coachroof is on, Decks are laid |

View showing Lucy Trindar working on the Cargo Hatch Coamings & Foc's'le Booby Hatch |

The inner plank components of the hollow A-frame Bulwarks are going on |

Davina grinning at the camera man--Xynole-polyester fabric & epoxy going over all exterior surfaces |

Lucy grinning at Davina |

Fabric/epoxy--Center Cockpit Coamings and Cabin centered |

The Booby Hatch to the Aft Cabin gettin Xynole & epoxy |

All exterior fabric covering is complete, and epoxy primer has been applied over all |

View from the port bow. I repainted the yellow because I didn't like the color |

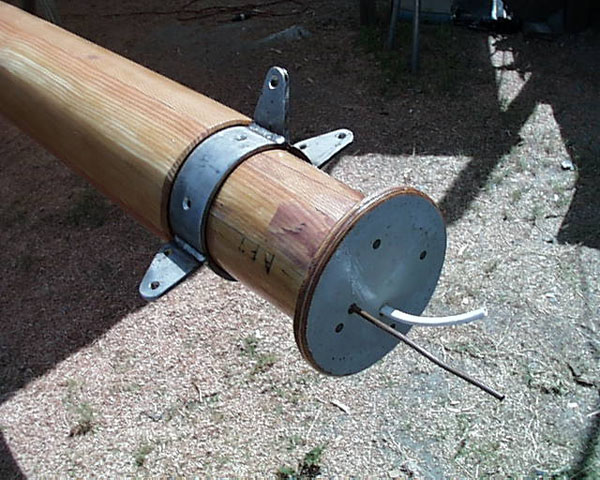

The Douglas fir mainmast being laminated, using the Herreschoff "Bird's Mouth" method |

Masthead showing lightning ground and wire for light; The mast collar is for a Junk Mains'l |

Mainmast shaped and epoxy sealed |

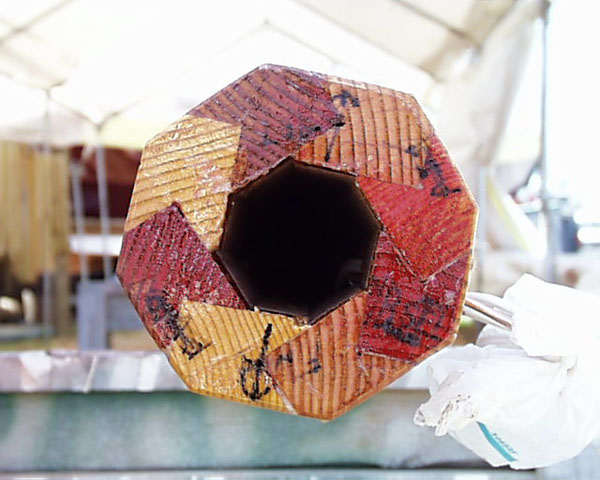

The Bird's Mouth mast lamination uses octagonal 8-wall sections with 45-degree cuts on one side. The locking joint thus created is very strong, providing large gluing surfaces, a mechanical joint, and thinner wall sections |

Shown are stacks of mast segments ready to be scarfed and laminated for two more masts |

The main boom and main yard are also laminated using the Bird's Mouth method |

Closeup of the main yard showing the use of large hose clamps in lamination |

Using a hand-held power plane to rough-shape spars |

Hose clamps are tightened (and loosened) with a battery-powered drill motor |

Mahogany bunk boards (and all trim) are epoxy-sealed & pre-finished with sprayed varnish prior to final installation |

"Miami teak" (Wolmanized pine) lifeline stanchions being oil-soaked prior to installation |

T'IEN HOU's solid bronze windlass, from Lunenburg Foundries in Nova Scotia |

Bill Smith welding the Naca 0009 foil-shaped fin portion of the retracting wing-keel |

Bill Smith welding the Naca 0009 foil-shaped fin portion of the retracting wing-keel |

The delta-wing portion of the keel being added to the fin |

Close-up view showing the pipe leading edge and foil shaped delta wings |

The delta-wing sides are being welded on |

Bill is welding the trailing edge closed--tricky work |

Rudder Core components before assembly |

The core has been assembled; plywood skins laminated over; and the endplate is being laminated |

The endplate is sculpted, filleted and ready for Xynole/epoxy |

Rudder installed in hull; Gudgeon being made (the cut-off wedge allows rudder removal) |

The gallery window teak trim being installed--the red paint is Dupont Industrial Imron |

Deck perimeters have been sprayed with buff LP; Ready for non-skid |

Nonskid applied (sand-blasting sand sprinkled in wet epoxy primer, LP overcoated) |

The Isuzu 3LD2 (38hp) diesel installed; It proved to be inadequate and was replaced with a Yanmar 4JH4 (54hp) |

The helm station, with 36" destroyer wheel |

The aft cabin & Gallery Windows from inside before trim |

The steering machinery platform with rudder shaft & gear ready for installation |

The Gallery Windows |

T'IEN HOU in the slings about to be launched; Wing Keel in down position; Abaco Dinghy in davits |

View from forward showing kayak 2nd tender; Yachtsman anchor catted & fished |

Prop apperture & rudder, showing sculpted end-plate & counterbalance |

The retracting Wing Keel in the down position; It weighs 3,500lbs and provides self-righting to a nearly inverted position; It is lifted by twin Warn ATV cable winches |

The Abaco Dinghy (sponging skiff) in the stern davits |

T'IEN HOU sailing in Maine, showing off her ketch rig |