REVIVING A CLASSIC

THE TERRAPIN SERIES

BY Reuel B. Parker

The Terrapin 34 TOMFOOLERY under sail in the Florida Keys

A long time ago, I came across a pair of marvelous books on wooden boatbuilding by Harry Sucher: Simplified Boatbuilding—The Flat-Bottom Boat, and Simplified Boatbuilding—The V-bottom Boat. Both were published in 1973 by W.W. Norton & Co. I still cherish my well-worn first-edition copies. Browsing through the second book I came across a “33’ Modified Sharpie Terrapin Schooner” on pages 283, 284 & 285. Sucher’s plan shows a flat-bottomed hull with increasing deadrise in the quarters to the transom. The little schooner has low-freeboard, twin houses (very low), and a self-tending gaff schooner rig. The bottom is cross-planked forward, and file-planked aft, in the deadrise part of the hull. Sucher claims that his design is based on “terrapin schooners” from the 1880’s that were used in the turtle fisheries in Florida and the Gulf of Mexico. I believed him, of course, and for many years I thought that’s where they originated.

Two decades or so later, when I started my research for The Sharpie Book, I turned up information (and a sketch) in Howard I. Chapelle’s The National Watercraft Collection (U.S. National Museum Bulletin 219; 1960), garnered in turn from Small Yachts: Their Design and Construction, Exemplified by the Ruling Types of Modern Practice by C.P. Kunhardt (1886). It turns out that the terrapin schooners were actually sharpie fishing smacks used on the Chesapeake Bay and waters southward.

Kunhardt’s drawing of a terrapin smack, from Forest and Stream, 1885

What defines a “smack” is a wet fish hold, created by isolating the large middle portion of a vessel’s hull with watertight bulkheads, and drilling small holes in the bottom to flood the hold. Fish in the hold will thereby have a healthy environment to thrive in until they can be taken to market. No ice required. This would work well for keeping turtles also, but I have never found a reference (other than Sucher’s) that the smacks were so used. It seems plausible that they were, even though they were certainly inshore fishermen. I can envision them sailing along the Southeast Florida coast, harvesting turtles swimming off the beach after laying their eggs.

Chapelle also described the terrapin smacks, in more detail, in Paper 25: The Migrations of an American Boat Type (1961—Library of Congress), including a Lines Drawing.

Chapelle’s lines drawing of a Maryland Terrapin Smack, based on a wreck, sketches, photographs, and dimensions given by Kunhardt— from Paper 25 (Library of Congress)

The dimensions of Chapelle’s terrapin smack are 37’ 10 ½” between perpendiculars, 9’ beam, and 1’ 7 ¼” draft. The wet well is divided in half by the centerboard trunk.

It is of note that Chapelle’s drawing has no deadrise aft, which made me speculate that Sucher may have added it of his own volition (a common modification), except that if you look closely at Kunhardt’s sketch, you can just see deadrise at the transom. It is also of note that a similar type existed on the Chesapeake Bay, which did have a flat bottom forward with deadrise aft, and was known as the Hampton Flattie. These varied in size from 16’ to 30’, according to Kunhardt, who wrote about them also for Forest and Stream. The “flattie” models were smaller than the “terrapin” models, and were rigged as gaff sloops. Chapelle found a hulk near Elliot, Maryland, about 1940, and drew plans based on it. The flatties were used for oystering and crabbing, while the terrapins seem to have all been fishermen (smacks). (I sell plans for a 24-foot “flattie” sharpie.)

In the mid-1980’s, two friends approached me with a request for an extreme shoal-draft, low-cost, charter bareboat for the Indian River area of Florida’s east coast. I designed my own Terrapin Schooner in response. My first hull lines were for an arc-bottom modified sharpie 34’ between perpendiculars, 10’ beam and 2’ 3” draft. I later designed a second version (of the same dimensions) with deadrise forward (V bow sections), which I felt would be more seaworthy, and which would not pound (the nemesis of sharpie hulls).

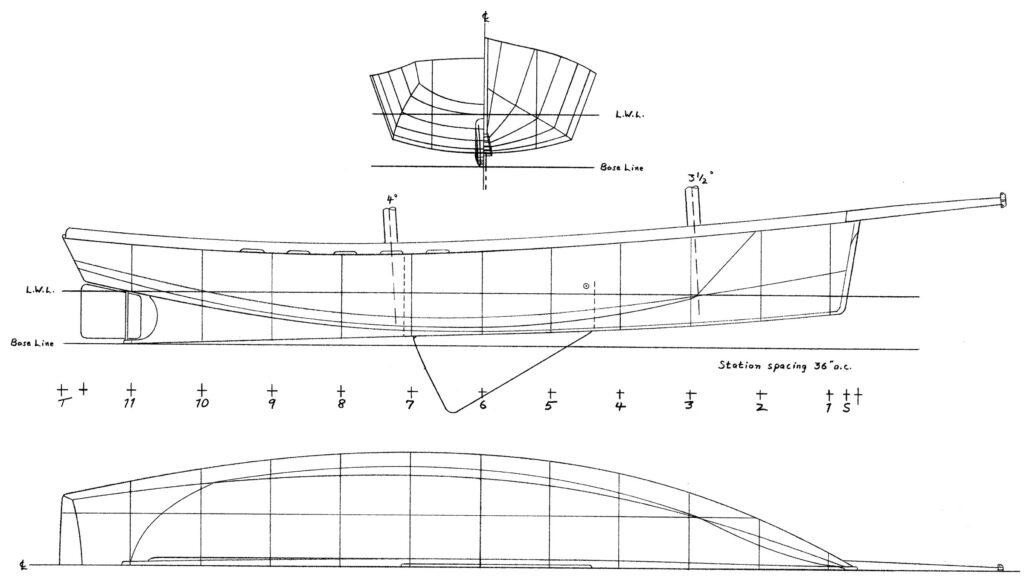

The Lines for my deadrise (arc-bottom) Terrapin 34 design

I designed my terrapin to be a simple cruising sailboat, with the hope that several would be built and rented as “bare boats” out of Ft. Pierce, on the Indian River. I should mention here that the Indian River is a long, narrow, shallow estuarine lagoon, protected by barrier islands, teeming with wildlife of great diversity. There is excellent fishing and collecting of clams and oysters in season. There are many endangered manatees. The bird life alone is fantastic. Wildlife enthusiasts could easily spend a week cruising the Indian River from Stuart to Cape Canaveral, stopping to anchor each night in protected coves. There are numerous parks and wildlife refuges right on the water. My terrapin would be equally at home in Florida Bay, the Keys, the Bahamas, and cruising the coasts of the southeastern United States. She would also be an excellent choice for Mississippi, Georgia, the Carolinas, Chesapeake Bay, and the shallow inland waters of New Jersey.

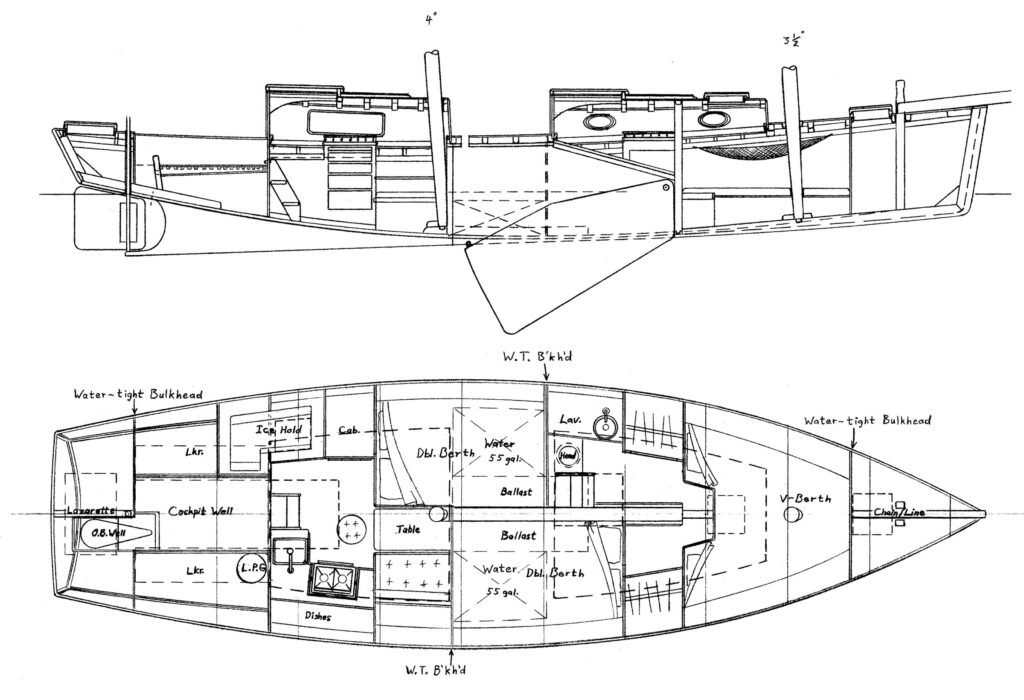

Plan & inboard profile for the Terrapin 34 cruiser

Unfortunately, the bareboat enterprise never materialized (I still believe it was a great idea), and I relegated my design to the status of “stock plan.” But in 1989 I received a phone call from a retired colonel in Texas, who said he was driving to my Islamorada boatyard (in the Florida Keys) to meet me. I tried to discourage him, until he mentioned that he was bringing money!

Even though it was very late in our “building season” (neither I nor epoxy can tolerate the Florida heat between May and November), we started construction on the first Terrapin 34 schooner in April of 1989, and launched the finished TOMFOOLERY sixteen weeks later that July.

The first Terrapin 34 in frame, Islamorada, Florida, 1989—note the refrigerator (upper left corner) required for controlling epoxy curing times in high heat conditions

During the design process for the Terrapin 34 I had chosen a simplified version of my usual method for cold-molded hull construction, which I dubbed “quick-molding.” This involved double-diagonal planking the hull bottom using the thickest plywood planking that could take the curves involved, and full-sheet 5/8” (actually 19/32”) plywood for the topsides planking, joined by butt-blocks. For the first Terrapin hull I specified 5/8” BBOES plywood, used in forming concrete. This yellow pine plywood seemed to be of very good quality, with almost no core-laps or voids, thick surface veneers, and very few “footballs” (knot-plugs). The slightly oily surfaces bonded thoroughly to epoxy during my tests, and I really thought I was on to something! (I am always searching for good, cheap plywood….)

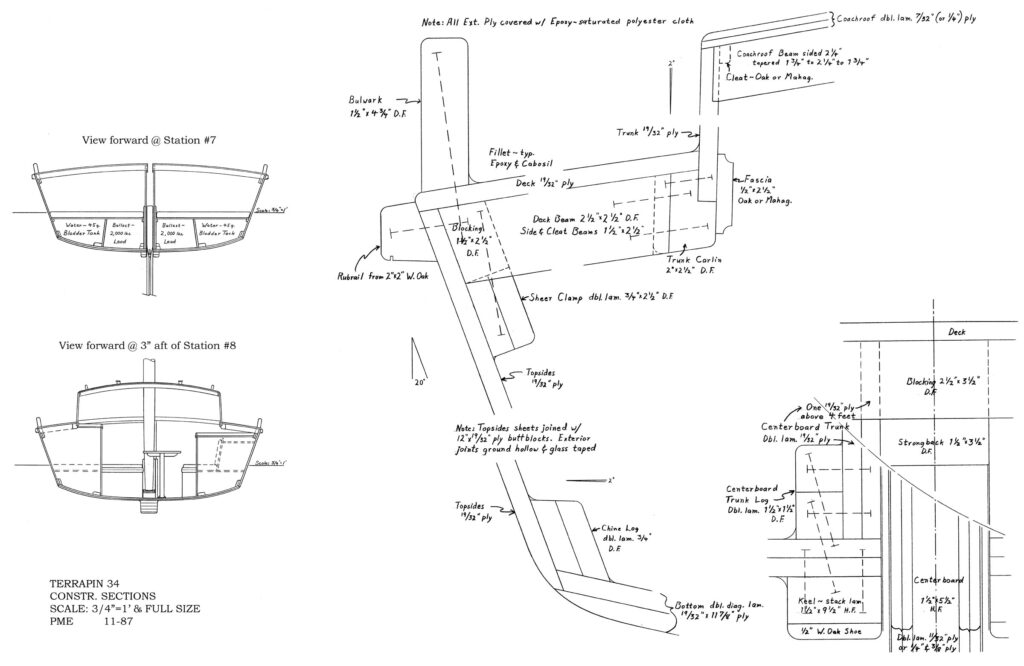

Construction Sections for the Terrapin 34

Construction went rapidly and well, with a crew of six. I divided my work force into two and sometimes three crews, each with separate projects. Thus we were simultaneously building the hull, centerboard and rudder, spars, and making custom stainless-steel hardware.

Diagonal Planking—first layer

The hull went together easily and quickly, although we broke a couple of planks on the curvaceous stern. Decks consisted of the same 5/8” plywood, laid over sawn Douglas fir beams.

Solid Douglas fir deckbeams and carlins being installed—note the solid blocking used between the beam-ends on the shelves

Masts were got out of solid full-dimension 6×6 air-dried Douglas fir timbers, and booms and gaffs from smaller fir timbers.

Masts came from fir timbers, laid out square, tapered, and octagonal

The masts were then power-planed, sanded, epoxy sealed, primed, and painted

The interior consisted of painted plywood trimmed with varnished mahogany—simple but elegant. The colonel specified that no thru-hulls be installed, so I gave him a removable basin whose contents he could toss overboard. The head consisted of a similar arrangement. There was also a large ice hold, and a two-burner stove. Total materials costs, including outboard motor, sails, upholstery and rigging, were $24,000. Labor was about twice that figure.

The plywood interior being roughed in – Icebox, Galley Drawers, Double Berth

Power consisted of a 4-stroke Yamaha 9.9hp outboard located in a well in the cockpit. Sails and running rigging were Dacron; anchor rodes and dock lines were Nylon (I spliced the rodes to 5/16” hot-dipped galvanized chain), and standing rigging was hand-spliced 5/16” stainless-steel, with galvanized rigging screws and stainless-steel chain plates. All exterior surfaces were covered with epoxy-saturated Xynole-polyester cloth—with two layers on the bottom. All exterior paint was polyurethane over epoxy primers. Bulwarks were Douglas fir finished bright.

We launched TOMFOOLERY in July, and she was a pretty sight.

Launching TOMFOOLERY in July, 1989—the author is to the right of the centerboard

The colonel and his wife came for sail trials, and to take TOMFOOLERY home to Texas with a hired captain. The little schooner sailed fast, was stiff, balanced, pointed well, and was quick in stays—never missed a tack. I felt she motored well, but the colonel thought she should do better, and tried putting the outboard on a transom bracket (not a good idea).

The Terrapin 34 TOMFOOLERY sailing

To the best of my knowledge, there has never been a revival of terrapin schooners. It seems that these beautiful, pragmatic workboats have been lost in the corridors of time. In all the years I have offered plans for my Terrapin 34, I don’t know for certain of another one being built.

I eventually designed a Terrapin 42, of which at least two were built (the first being OYSTER—built by my partner Bill Smith in Ft. Pierce in 1993/4); a Terrapin 25 (SKIMMER—also built by Bill Smith in Ft. Pierce in 1991); a Terrapin 21 (built by Bill Oelrich); a Terrapin 30 (Built by Doug Ferrell); and a Terrapin 16 (none known). My smaller Terrapins are gaff-rigged sloops, like the Hampton Flatties.

The Terrapin 25 was the prototype for the Creative Marine Skimmer 25 GRP production sailboat, produced from 1992 to 2002. Molds were pulled from her hull and decks.

The Terrapin 25 SKIMMER sailing off Key West, built in 1991

The Terrapin 42 schooner OYSTER, built in 1993/4

A Terrapin 30 by Doug Ferrell

A Terrapin 21 by Bill Oelrich

Every once in a while someone from Texas will tell me that TOMFOOLERY is alive and well, under different owners, and that she still turns heads wherever she sails. Long may she live!

* * *

The Terrapin Series Designs are available from Parker Marine Enterprises. Website: www.parker-marine.com. They can be seen in the Catalogue of Cruising Sail.